About SGS-Doors A/S

SGS-Doors A/S (short for Snedker Gaarden Sunds) was founded by Leif Pedersen in 1995, initially with the manufacture of various types of joinery, turntables, fixtures and fittings – and at the same time primarily laminate fronts for several Danish kitchen factories. The latter activity was developed into “a la carte”, i.e. kitchen-ready delivery in sizes/quantities to the kitchen factory’s individual needs, so that the products were delivered “just-in-time” – in order to minimize the kitchen factories’ need for costly stocking of “wrong” front sizes and quantities.

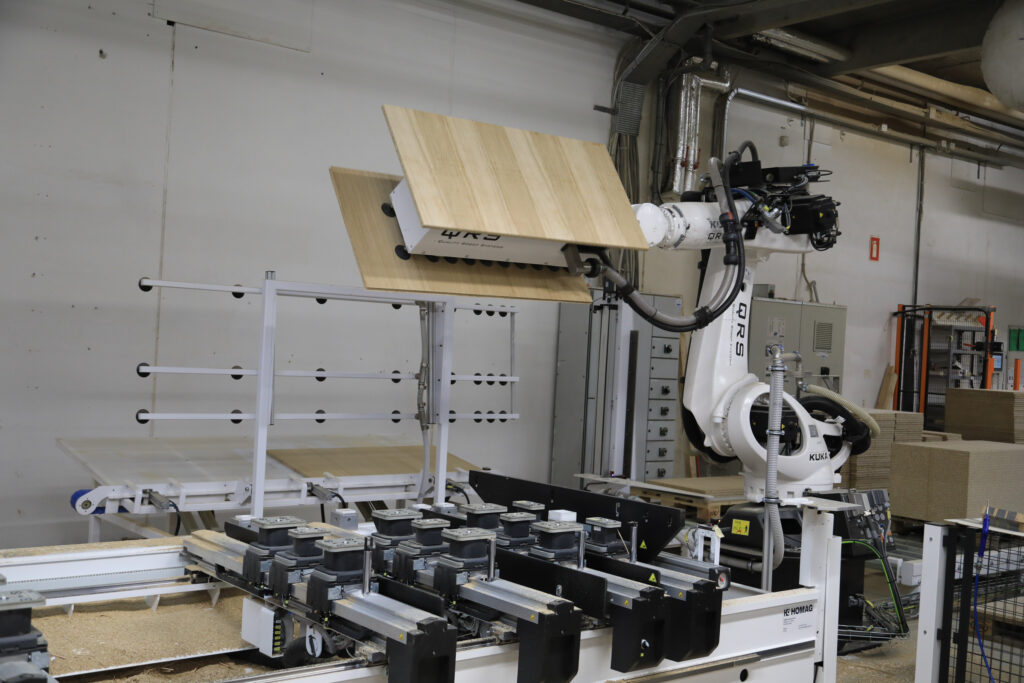

The idea has been successfully maintained and significantly expanded in recent years. Controlled growth has meant that the production area was gradually expanded, especially with a major investment in sheet metal cutting plants. Most recently, in 2009, SGS-Doors took over Denmark’s largest front factory facility in Ikast. 11,500 m2 of production area with adjoining commercial land to potentially expand to at least double. The relocation of production facilities and investments in the latest CNC and sheet metal cutting technology were implemented in 2013. And in 2019, a robot cell that feeds an automatic CNC was introduced. In the summer of 2020, the 22-year-old traverse paint system was replaced as well as a new cleaning machine for removing impurities. In the spring of 2024, the first 5-axis Homag CNC for SGS-Doors was installed in production.

Larger series are also produced, especially of painted MDF fronts, veneer, laminate and melamine items for the kitchen and furniture industry. However, the idea of developing the “a la carte” and “just-in-time” concept remains a top priority, and the front range for this segment is being expanded week by week and month by month, which over the past few years has meant that SGS-Doors is now among the leading Scandinavian manufacturers of kitchen and cabinet doors with more than 65 employees. Exports to Norway and Sweden currently account for about 35% of the total turnover.

SGS-Door’s primary business idea is to produce customer-specified front designs, just as special products for other interior design tasks make up a significant part of the production. It is the company’s firm goal to implement the highest possible degree of production processing. The most advanced form of production and production management and the most future-proof physical material handling in the form of the latest investments in modern robot technology, among other things. Our customers are of course the most important part of this goal!