Om SGS-Doors A/S

SGS-Doors A/S (forkortelse af Snedker Gaarden Sunds) etableredes af Leif Pedersen i 1995, indledningsvis med fremstilling af forskellige former for snedker-, drejer og inventar-arbejde og sideløbende primært laminatlåger til flere danske køkkenfabriker. Sidstnævnte aktivitet blev udviklet til “ a la carte”, d.v.s. køkkenvis levering nøje i størrelser/kvanta til køkkenfabrikkens individuelle behov, således at der leveres “just-in-time” for derved at minimere køkkenfabrikkernes behov for bekostelige lagerføringer af “forkerte” låge størrelser og antal.

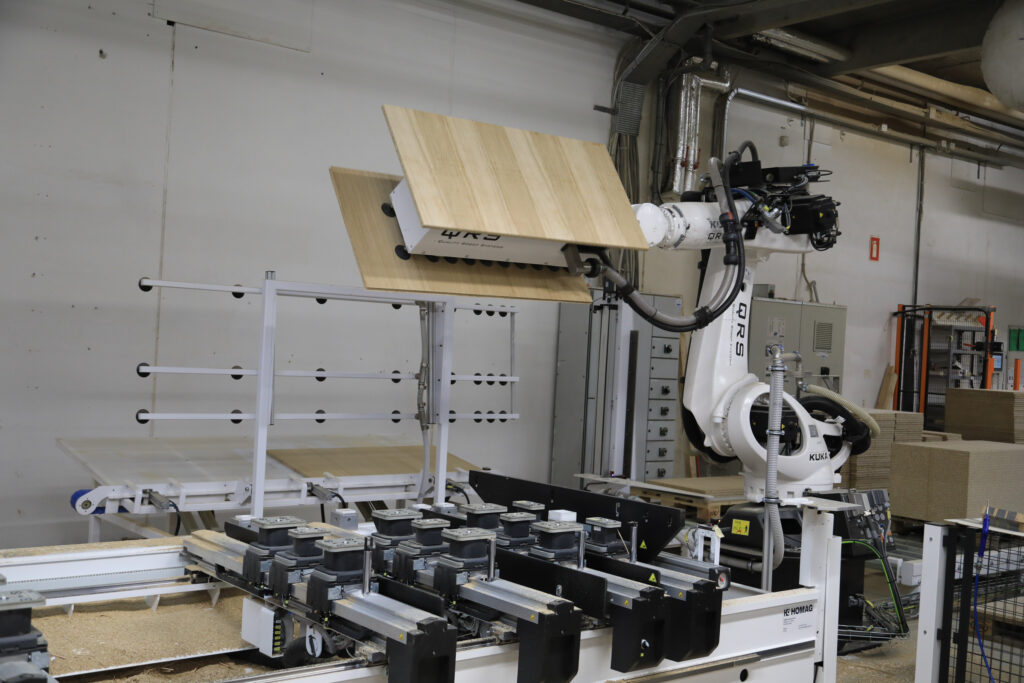

Ideen er med stor succes fastholdt og væsentlig udbygget de senere år. En kontrolleret vækst har betydet, at produktions-arealet trinvis blev udvidet, især med en større investering i pladeopskæringsanlæg. Senest har SGS-Doors i 2009 overtaget Danmark’s største lågefabriks-anlæg i Ikast på 11.500 m2 produktionsareal med tilliggende erhvervsgrund til potentielt at udvide til mindst det dobbelte. Flytningen af produktionsanlæg og investeringer i nyeste CNC- og pladeopskærings-teknologi er implementeret i 2013. Samt i 2019 kom en robot celle der føder en automatisk CNC. Sommeren 2020 blev det 22 år gamle travers lak anlæg udskiftet samt ny rensemaskine til fjernelse af urenheder. I foråret 2024 blev den første 5 akslet Homag CNC til SGS-Doors installeret i produktionen.

Der produceres også større serier, især af malede MDF-låger, finer, laminat og melamin emner til køkken- og inventarindustrien. Ideen med at udvikle “a la carte” og “just-in-time” konceptet har dog fortsat højeste prioritet og lågeprogrammet til dette segment udbygges uge for uge og måned for måned, hvilket over de seneste par år har bevirket, at SGS-Doors nu med mere end 65 ansatte er blandt de førende skandinaviske producenter af køkken- og skabslåger. Eksporten til Norge og Sverige udgør p.t. ca. 35% af den samlede omsætning.

Det er SGS-Doors primære forretningside at producere kunde-specificerede lågedesigns, ligesom specielle produkter til andre indretningsopgaver udgør en betydelig del af produktionen. Det er virksomhedens faste mål at implementere den højest tænkelige grad af produktionsforædling. Den mest avancerede form for produktion- og produktionsstyring og den mest fremtidssikrede fysiske materialehåndtering i form af de seneste investeringer i bl.a. moderne robot-teknologi. Vore kunder er naturligvis den vigtigste del i denne målsætning!